When it comes to manufacturing and logistics, efficient packaging and palletizing operations are critical for meeting customer demands and maintaining a competitive edge. Traditional manual processes can be labor-intensive, prone to errors, and struggle to keep up with increasing production volumes. Enter packaging and palletizing robots — the transformative solution that’s revolutionizing the way goods are prepared for shipment.

Unpacking the Benefits of Robotic Packaging and Palletizing

The integration of robots into packaging and palletizing processes brings a multitude of advantages that can significantly impact a company’s bottom line and operational efficiency. Let’s look deeper into some of the most compelling benefits:

Enhanced Productivity

Robots can significantly increase throughput and reduce lead times. They perform tasks consistently, even during peak demand periods.

- Non-Stop Operation: Unlike human workers, robots can operate continuously without needing breaks or rest, leading to increased throughput and faster turnaround times. This 24/7 capability is particularly valuable in industries with high demand or seasonal peaks.

- Speed and Precision: Robots execute tasks with exceptional speed and accuracy, minimizing errors and ensuring consistent output. This translates to improved productivity and reduced waste.

- Adaptability: Modern robotic systems are highly adaptable and can be reprogrammed to handle different product types or packaging configurations, providing flexibility to meet evolving market demands.

Improved Accuracy and Consistency

Robots eliminate human error, meaning reduced product damage, fewer returns, and a better customer experience.

- Error Reduction: Human error is inevitable in manual packaging and palletizing processes. Robots eliminate these errors, ensuring precise product placement, label application, and palletizing patterns.

- Product Protection: Consistent handling and accurate palletizing minimize product damage during transit and storage, leading to fewer returns and increased customer satisfaction.

- Traceability: Robotic systems can be integrated with data tracking and management systems, providing valuable insights into production and enabling better quality control.

Enhanced Safety

Manual packaging and palletizing can lead to injuries. Robots can handle these tasks easily, minimizing the risk of workplace accidents and creating a safer environment for workers.

- Ergonomic Relief: Packaging and palletizing often involve repetitive motions and heavy lifting, which can lead to musculoskeletal injuries. Robots take on these physically demanding tasks, reducing the risk of workplace injuries and improving employee well-being.

- Hazard Mitigation: Robots can handle hazardous materials or operate in environments that pose risks to human workers, such as extreme temperatures or exposure to chemicals.

Space Optimization

Robots can be designed to operate almost anywhere, potentially freeing up valuable floor space.

- Compact Footprint: Robots can be designed to operate in confined spaces, maximizing floor space utilization in warehouses and manufacturing facilities.

- Flexible Deployment: Robotic systems can be easily redeployed or reconfigured to accommodate changes in production layouts or product lines, providing greater operational flexibility.

Cost Savings

Despite the investment cost, the long-term benefits outweigh those costs:

- Reduced Labor Spend: Although the initial investment in robotic systems can be substantial, the long-term savings in labor costs can be significant. Robots reduce the need for manual labor, freeing up employees for higher-value tasks.

- Minimized Waste: Improved accuracy and consistency lead to reduced product damage and material waste, resulting in cost savings.

- Increased Efficiency: Streamlined operations and optimized processes contribute to overall cost reductions and improved profitability.

Technological Advancements Driving Innovation

The field of robotics is undergoing a rapid transformation fueled by breakthroughs in various technologies. These advancements are not only enhancing the capabilities of packaging and palletizing robots but also opening up new possibilities for innovation and efficiency in the industry. Let’s explore some of the most significant developments.

Vision Systems

Advanced vision systems enable robots to identify and handle a wide variety of products.

- Enhanced Object Recognition: Advanced vision systems, equipped with high-resolution cameras and sophisticated software, have revolutionized how robots perceive their surroundings. These systems enable robots to accurately identify and locate a wide range of products, even those with complex shapes, varying sizes, or reflective surfaces.

- Real-time Adaptation: With the power of vision, robots can adapt to changes in product orientation or position in real time. This dynamic capability ensures seamless handling and minimizes errors, even in fast-paced production environments.

- Quality Control: Vision systems also play a crucial role in quality control. By inspecting products for defects or inconsistencies, these systems can help identify and remove faulty items from the production line, ensuring only high-quality products reach the customer.

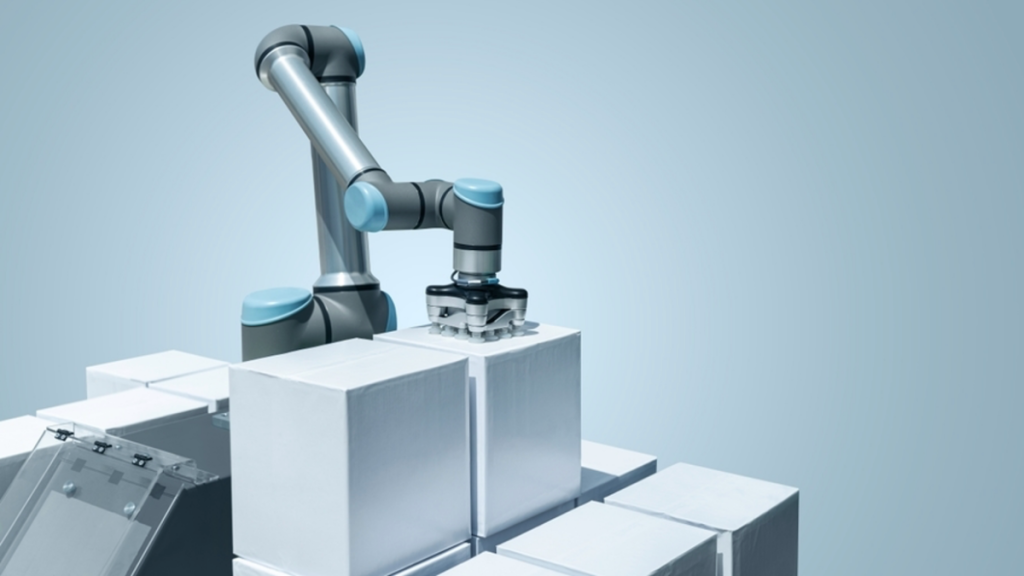

Collaborative Robots (Cobots)

Cobots are designed to work safely alongside humans, allowing for greater flexibility and collaboration in packaging processes.

- Safe Interaction: The rise of collaborative robots, or cobots, has transformed how humans and robots interact in the workplace. Cobots are designed with safety features, such as force sensors and collision detection systems, that allow them to work safely alongside humans without needing physical barriers or cages.

- Flexibility and Adaptability: Cobots are highly versatile and can be easily reprogrammed and redeployed to perform a variety of tasks. This adaptability makes them ideal for packaging and palletizing operations, where product types and packaging configurations may change frequently.

- Enhanced Productivity: Cobots can handle repetitive or physically demanding tasks, freeing up human workers to focus on more complex or value-added activities. This collaboration between humans and robots can lead to increased productivity and efficiency.

Artificial Intelligence (AI)

AI algorithms enable robots to learn and adapt to changing conditions, further improving their efficiency and performance.

- Machine Learning: AI algorithms, particularly machine learning, allow robots to learn from experience and continuously improve their performance over time. This allows them to optimize their movements, adapt to new situations, and handle unexpected variations in products or packaging.

- Predictive Maintenance: AI-powered analytics can monitor the health and performance of robotic systems, predicting potential maintenance issues before they cause downtime. This proactive approach helps to maximize uptime and minimize disruptions to production.

- Process Optimization: By analyzing vast amounts of production data, AI can identify bottlenecks or inefficiencies in packaging and palletizing processes. These insights enable continuous improvement and optimization, leading to greater efficiency and cost savings.

Partnering with Robotic Integration Experts

Implementing robotic packaging and palletizing solutions requires careful planning and integration. Partnering with experienced automation integrators can ensure a seamless transition and maximize the benefits of robotics. They can assess your specific needs, recommend the right robotic solutions, and provide ongoing support to ensure optimal performance.

Embracing the Robotic Future of Packaging

Packaging and palletizing robots are transforming the way goods are prepared for shipment. By embracing this technology, manufacturers and logistics providers can streamline operations, improve efficiency, and gain a competitive advantage in the market. Don’t get left behind.

Laila Azzahra is a professional writer and blogger that loves to write about technology, business, entertainment, science, and health.