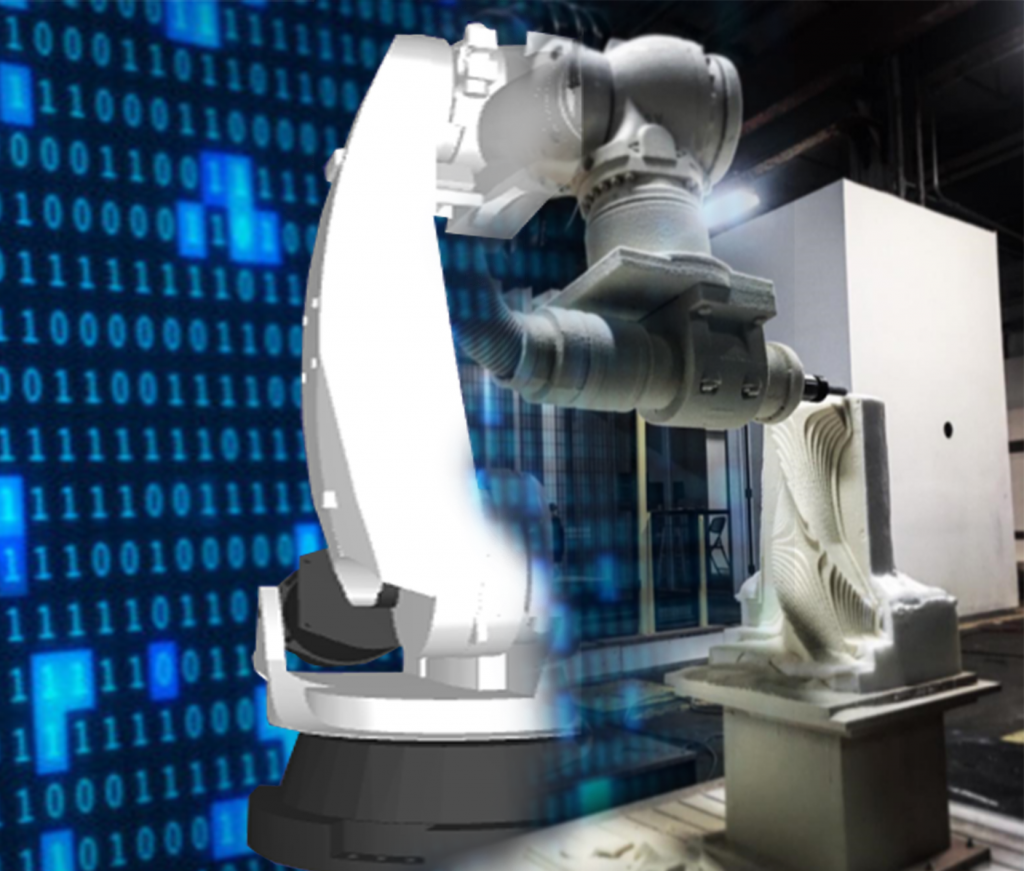

CNC, or Computer Numerical Control precision machines utilize computers in order to make very precise cuts. The specialized and sophisticated equipment shines within the manufacturing industry due to its versatility and usefulness.

Computer-controlled machines may be used for different applications, including high speed milling, grinding, mills and lathes.

How Does CNC Precision Engineering Machining Work?

The precision machine is fed numerical controls so it can understand what the end product is and where and how deep to cut. More often than not, a program is needed to make a particular item. A precision milling tool, for example reads a machine language specifically made for CNCs, e.g., the G-code, which allows for accurate cuts.

Moreover, the code will determine the object that will be made in the end. Some of the information the G-code will specify include coordination, positioning, location, feed rate, velocity and speeds.

CNC precision engineering machining can create a specific part or standalone product with materials such as metal, plastic and more. The turned parts will be able to fit in perfectly as a cog or by itself.

Benefits of CNC Machining

CNC machines are not an absolute must-have for all manufacturing processes, but they do possess unique characteristics that can save your business time and money, among other things.

For making everyday screws and bolts, a CNC machine may not be needed, but it does shine in parts that need closer scrutiny. In custom metal milling, CNC machines allow you to make a part duplicated effortlessly as much as you need it.

3D parts can also be manufactured with the CNC machine. All it needs is a 3D or 2D CAD drawing and customized G-Codes to put the tool in action. Moreover, this kind of equipment is best for when you need to make difficult patterns or odd shapes repeatedly.

Laila Azzahra is a professional writer and blogger that loves to write about technology, business, entertainment, science, and health.