Speaking of vehicles, we can quickly think of the comfort of it, but where does the control of comfort come from? Most people might think of shock absorber since it is the primary control to ensure the stability and ride comfort of the car, but the comfort controller is far more than that. Many rubber products on the vehicle are accessories to ensure the stability and ride, such as rubber bushing, a component to ensure the balance. We would go through its general knowledge, function, and classification, etc. in the article.

Function and working principle of car bushings

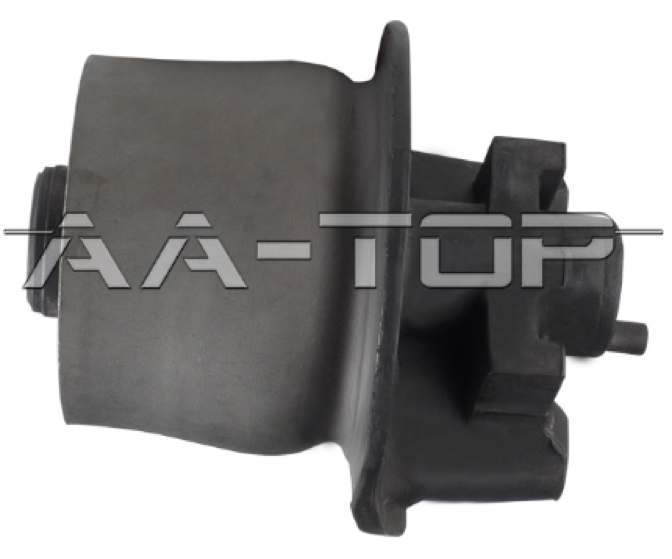

The automotive bushing is divided into conventional rubber bushing and hydraulic rubber bushing. It belongs to the rubber parts of automobile chassis and is the hinge point between various parts of the automobile body. Its elastic characteristics and attenuation characteristics are superior. It can bear the load, isolate, attenuate vibration, reduce noise, and ensure the ride comfort, having an essential impact on the design of automobile suspension.

Rubber bushing is the most common type of car bushing. It is operated in a limited range without lubrication. The rubber bushing is usually used in control arms and spring sheets. To eliminate wear surface, people always combine rubber bushing with inner and outer metal sleeves. The outer sleeve is usually pressed into the control arm or spring, while the inner sleeve is fixed to the frame by a fixed bolt. High-quality rubber bushing absorbs the torsional motion of suspension components. Thus no friction or rotational wear occurs. Wear problems arise only when the rubber bushing is separated from the inner sleeve and the outer sleeve.

Rubber bushing is designed to control noise from the road and vibration by chassis. Ozone, ultraviolet, extreme temperature, and other problems will harden the rubber bushing, resulting in noise and vibration of it.

Usage and classification of car bushings

The car bushings are commonly used in these automobile parts: 1) control arm, 2) stabilizer rod, 3) shock absorber, 4) sub-frame, 5) differential, etc. Rubber bushings can be divided into compression type, shear-type, and composite type according to its shape.

1.Compressed rubber bushing: mostly used in situations of large load and a small allowance of rubber space. It is an outer and inner cylinder, which can be divided into two types: common type and two-body type. Compressed internal free area can be reduced to vertical or axial stiffness, which is the ratio of radial or transverse stiffness and can reduce compressed stiffness. The middle bonded plate can increase its value and can bear a large load under the same cross-section area.

2. Shear rubber bushing

3. Composite rubber bushing: When the stiffness ratio of the above two kinds can not meet the requirements, composite rubber bushings are used, which can withstand shear and compression loads. It can be divided into standard type and no inner cylinder.

Selection of car bushings

It is suggested that when we choose rubber bushing in the future, we can select the most suitable and high-quality products to ensure the stability of the car. And it’s a warning that the value of rubber bushing in automobiles can not be merely measured by price since rubber bushing is irreplaceable.

Rubber bushings are highly recommended among all the car bushings. For it has more freedom of choices, the stiffness of three directions (axial, radial, and torsional) can be selected appropriately. And it can be vulcanized firmly with metal, which simplifies the structure of fixing and supporting. The elastic modulus of rubber is smaller than that of ore, which can produce more extensive elastic deformation. What’s more, the internal friction of rubber is larger than that of metal and tends to increase with frequency. Therefore, the resonance amplitude can be reduced by using rubber bushing. Lastly, the dynamic elasticity coefficient of rubber will rise sharply at low temperature. When choosing rubber bushing material, we should try to improve the high temperature, low temperature, and oil resistance of the material. Among all the company, I should say AA-TOP is a reliable and high-end manufacturer. Having specialized in the suspension parts supply field for many years, AA-TOP has the processing technique, source supply, product quality ranking on the top. You can choose any car bushings you need by the brand, car model, engine, etc.

Have you learned enough about car bushings? Next time if you are aiming for a superior car bushing, you might as well think of AA-TOP.

Laila Azzahra is a professional writer and blogger that loves to write about technology, business, entertainment, science, and health.