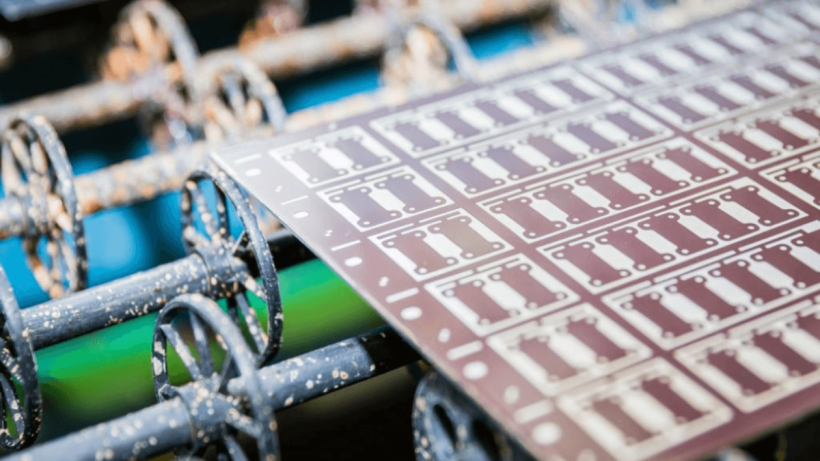

Photochemical etching is a process used to control the depth and shape of holes or recesses in thin metal parts. It involves using stencils, photoresist coating, UV light exposure, and developer solutions to create a pattern on the part’s surface. Before you hire best photochemical etching company lets learn more about photo chemical etching company.

What is photo chemical etching?

Photochemical etching services is a process that uses a photochemical reaction to remove metal from the surface of a material. The process takes place in two stages: photochemical treatment and mechanical removal. Photochemical etching company treats the surface with light by imprinting a pattern onto it and then chemically removing unwanted material by dissolving it with an acid solution. lets learn more about photo chemical etching

The process first requires preparing the part to be etched, typically by coating the metal with an acid-resistant layer or applying masking tape to certain areas. Once this is done and you’re ready for immersion into your chemical bath, put on safety goggles and gloves before handling any chemicals because they may be harmful if ingested or absorbed through your skin.

What type of materials can be used for photo chemical etching of thin metal parts?

Photo chemical etching services is used to produce thin metal parts, so you can use almost any type of material. It works best with steel, copper, and aluminum but is also effective on brass and zinc.

The process is similar to electroplating, where a thin layer of metal is applied to a substrate. The difference is that the coating you want is stripped away instead of added on top of the etching.

What parts can be created using photo chemical etching?

You can use photo chemical etching services to create thin metal parts and thin metal sheets of any size, shape, and thickness. A few examples of types of items that can be created using this process include:

- Thin metal foils

- Thin metal films

- Thin metal foams

- Thin metal membranes

Thin metal foils are thin metal sheets that can be used as a component in solar cells, fuel cells, batteries, and supercapacitors. Thin metal foams are thin metal parts that can be used as electrodes in fuel cells or batteries. Thin metal membranes can be created using this process to act as the separator between two active components of a battery or supercapacitor.

What are the benefits of photochemical etching?

Photochemical etching services are a relatively new method that has gained popularity over the past several years.

This process is ideal for quick, cost-effective, reliable thin metal parts with different shapes. A Photochemical etching company offers many benefits, including:

- Cost-effectiveness: With photochemical etching services, you can achieve high-quality results at a lower price than laser processing. One of the reasons why this process is so cost-effective is because it doesn’t require any expensive equipment or complicated processes; instead, all you need is photo chemicals and an ordinary tank filled with water.

- Speed: Photochemical etching company takes only minutes to complete the process, so you won’t have to wait long before getting your finished product. In addition, the speed at which it works also means that there isn’t as much risk involved because there aren’t many mistakes made during production time, so everything goes smoothly from start to finish.

- Durability: This method produces durable parts due mainly because they’re not susceptible to oxidization (rusting) like other methods tend towards over time due mainly because they’re not susceptible.

- Safety: The chemicals used in photo etching are safe for both users and the environment. This is because they’re non-flammable, won’t produce harmful fumes or gases, and are safe for the environment.

- Ease of use: This method is very easy to use, so it can be done by anyone without any special training or education.

Conclusion

Hope, this article helped you understand the basics of photochemical etching services for thin metal parts. This process is a great way to create intricate and detailed designs on small pieces of metal and larger ones.

Laila Azzahra is a professional writer and blogger that loves to write about technology, business, entertainment, science, and health.