The use of CNC machining has led to the production of various essential machine components, tools, and objects used in several industries. Its applications are many, notably in the creation of machine parts to the drilling of ornamental pieces. Utilizing programs and computer-aided design (CAD), cuts can be achieved with better precision and ease, all in a shorter time. Therefore, engineering capacity has improved because machine parts are produced faster, which has accelerated the productivity of fabrication specialists.

There are different CNC machines available in the industry, and what makes them different are the CNC machining parts and their functions.

What are CNC routers?

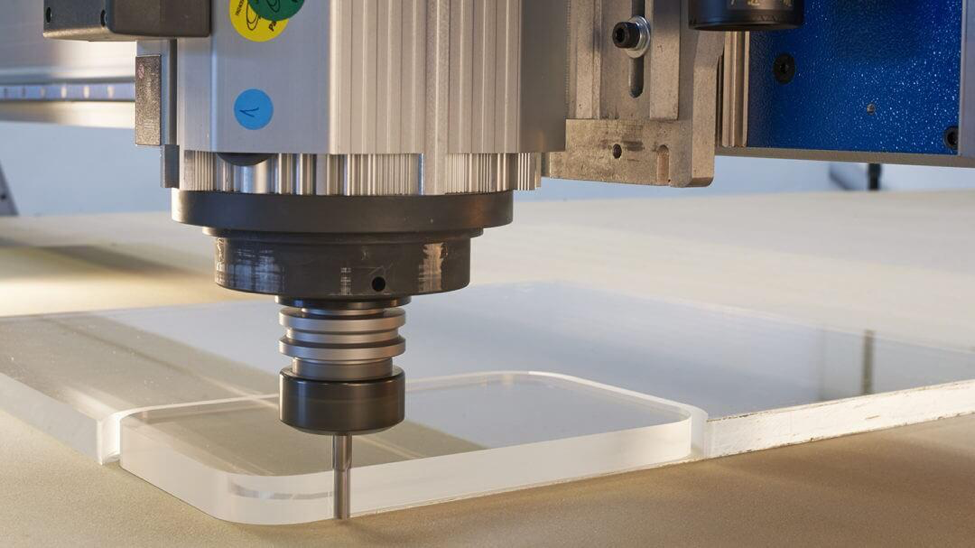

Fundamentally, a CNC router is a type of CNC machine that drills materials according to designs and codes that have been assigned, they are often confused with CNC mills because they perform similar functions. However, they are distinguished by the kind of material they can be used on, the CNC machining parts, and how it works.

CNC routers function by removing unwanted parts from the workpiece as per design. This method is called the subtractive technique and it starts with a mass (workpiece) that is eventually drilled into a desired 3D shape.

This type of CNC machine kit works fast, and they are suited for mass production. However, they can only be used with softer materials because it uses less torque. During the operation of the CNC machine kit, the spindle head rotates along the X, Y, and Z-axis to make the necessary cuts on the workpiece. The combination of the power used and how it works makes the cutting process faster, which is it is often used when large production is required.

Parts of CNC router

Different CNC machining parts come together to make the CNC router system. They are as follows:

- Spindle system: The spindle consists of different parts that hold the cutting system and it is controlled by a control system. It carries out movements that drive the cutting system according to the command sent from the control system.

- Bed Casting: This is a stationary section of the CNC system that holds the workpiece. Since it carries the load and must stay static despite dynamic force from cutting, this section must stay rigid and is often made up of cast iron.

- Control system: This includes the servo system, the numerical control system that controls all the CNC machining parts. The numerical control system dictates action while the servo system ensures accuracy.

- Automatic tool changer: The changer contains various tools in the magazine (drives, bucket, discs, etc.) that is loaded by a robot during machining. The command received from the numerical control system propels the robot to take the tool needed to the spindle.

- The auxiliary system: Controls maintenance procedures like lubrication, cooling, etc. that ensure the efficiency of the machine.

In conclusion, different CNC components come together to make up the CNC routers, each of which has to be changed regularly. You also need to purchase parts that are durable to withstand the job.

There are a variety of CNC parts manufacturers in the market. Choosing a suitable manufacturer is the greatest guarantee for your CNC machines. Bruico ensures that your cuts are properly executed by making the required CNC machining parts available to you. The company is comprised of a professional team that produces all your needed CNC machining parts that can be used in the aviation, electrical industries, etc.

Their 10 years of delivering industry-leading services have seen them sustain high qualities for every part manufactured which has served several CNC professionals. If you demand for CNC machining parts, please don’t hesitate to establish a long-term relationship with them.

Laila Azzahra is a professional writer and blogger that loves to write about technology, business, entertainment, science, and health.